Categories: Use Cases

Protection and Monetization of 3D-Printed Spare Parts

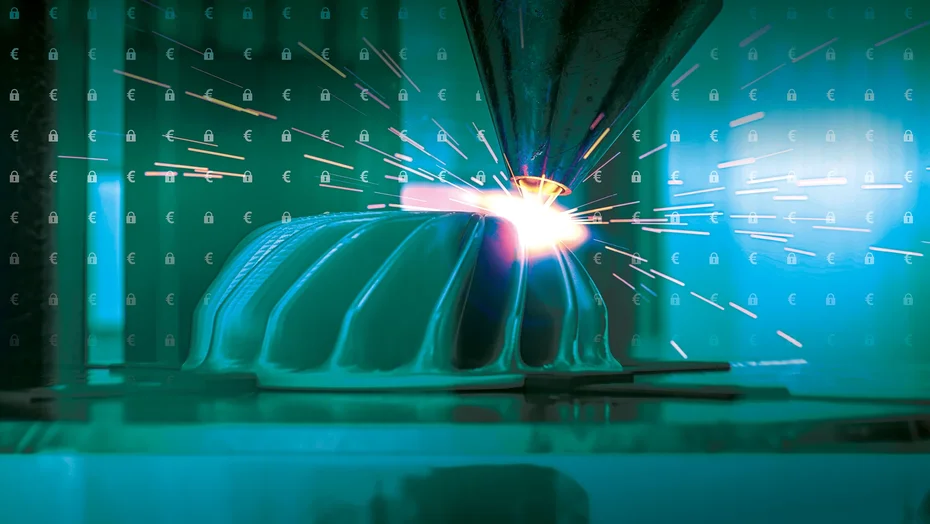

The additive manufacturing sector faces a dual challenge: safeguarding intellectual property and creating new revenue streams in the digital production chain. With its cutting-edge CodeMeter technology, Wibu-Systems addresses both aspects by ensuring that digital designs for 3D-printed spare parts are securely encrypted and managed, preventing unauthorized use and IP theft. At the same time, CodeMeter empowers manufacturers to monetize these digital assets through robust license management, offering flexible, on-demand production models. This integration of IP protection and licensing spans the entire process chain, from design to deployment, accelerating business operations, enhancing supply chain agility, and unlocking substantial market potential in industries that rely on timely, customizable, and cost-effective spare parts solutions.

The Challenges

The current challenges in the additive manufacturing (AM) market include both technological and economic aspects: Inflation, high financing costs, and low economic growth are impacting the investment budgets of SMEs, healthcare facilities, and traditional manufacturing businesses. Despite new technologies, the acquisition of capital-intensive 3D printing machines remains risky.

The Opportunities

Material development, particularly in the area of powder-based additive manufacturing, has accelerated, resulting in a wide variety of materials such as thermoplastics, resins, composites, and metal powders. This opens up new application possibilities in electronics, transportation, and medical technology, including biomaterials and organ printing. Advances in software development and automation are improving efficiency, quality, and reliability in the industrial context, which is crucial for competitiveness.

For instance, 3D plastic printing benefits from improved materials and new applications in the medical and automotive industries, increasing printing speed and accuracy. The use of 3D metal printing will continue to grow, as it enables the production of complex metal parts with less waste and lower costs, including safety-critical spare parts.

In this rapidly evolving landscape, ensuring secure processes and the use of certified materials not only guarantees consistent quality but also strengthens trust in the technology’s reliability, especially in sectors where precision and safety are paramount.

Besides its uncompromising focus on quality, AM also supports sustainability goals through on-demand production, reduced inventory, and the use of environmentally friendly materials, contributing to greater environmental neutrality across the value chain.

CodeMeter Technology

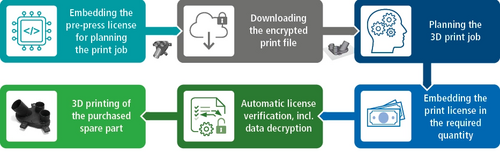

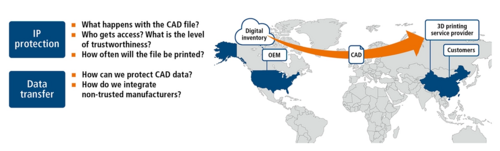

CodeMeter technology from Wibu-Systems ensures IP protection in 3D printing and simplifies licensing, especially in connection with ERP systems and web shops. Through encryption and access control, CodeMeter protects the integrity and confidentiality of 3D printing files, allowing only authorized users and machines to access them. This minimizes the risk of IP theft and unauthorized copying. Additionally, CodeMeter enables flexible and efficient management of licensing rights, allowing companies to sell licenses for the use of 3D printing designs and generate revenue from digital goods while controlling their usage.

The integration of CodeMeter into ERP systems automates the management of licenses and customer relationships, including orders, licensing, and billing for 3D printing designs. This centralizes relevant information and makes internal order processing more efficient. The connection to web shops enables the purchase of usage rights for 3D-printed products instead of selling the products themselves. Customers purchase licenses through the web shop, granting them the right to use specific 3D printing designs. CodeMeter manages these rights automatically and ensures a smooth process from product selection to license purchase, strengthening customer loyalty.

Case Studies and Applications

The 3D printing of spare parts in the automotive industry, particularly for trucks and buses, offers numerous advantages and innovative applications. One of the greatest benefits is the quick availability of spare parts, which can be manufactured on demand, especially useful for older models. 3D printing reduces production costs as no expensive tools or molds are required. It also enables customization and optimization of parts, improving performance and reducing weight. Complex geometries can be produced without additional costs, and on-demand printing eliminates the need for inventory storage.

A leading automotive manufacturer using 3D printing to produce spare parts would, for instance, reduce delivery times and minimize inventory. Spare parts would be offered digitally in a 3D printing license shop and could be printed directly on-site worldwide. Wibu-Systems’ CodeMeter technology would encrypt the 3D printing files and manage the licenses.

The research project ProCloud3D developed and tested a secure cloud-based platform for 3D printing, enabling decentralized, encrypted handling of all production steps. Key outcomes include realtime, end-to-end encryption for data and processes, digital rights management (DRM), and tamper-proof protection for 3D printers. This platform allows secure data transfer, licensing, and monitoring of 3D-printed parts, unlocking new business models while safeguarding intellectual property and production control.

Other industries, such as aerospace, medical technology, mechanical engineering, railways, shipbuilding, and defense, are also increasingly using 3D printing for spare parts.

Economic Perspectives and Future Outlook

The protection and licensing of 3D-printed spare parts open up significant economic opportunities and great market potential. By installing 3D printing services at key distribution centers, manufacturers can quickly respond to customer requests and print spare parts on-site, increasing customer satisfaction and loyalty. On-demand 3D printing significantly reduces inventory and logistics costs, particularly for rarely needed or obsolete parts.

3D-printed spare parts also offer the opportunity to serve hard-toreach markets, such as the vintage car market, where specific parts can be produced as needed. 3D printing enables customization and performance enhancements of parts. Manufacturers can tap into new revenue streams by licensing 3D printing files, allowing customers to purchase licenses for spare part designs and print them locally.

3D printing supports sustainable production methods by reducing material waste and optimizing logistics processes, promoting environmentally friendly products. Overall, the integration of 3D printing technologies in the industry offers possibilities for cost reduction, efficiency improvement, sustainability, and the opening of new markets and customer segments.