Formnext 2025

Formnext celebrates its 10th anniversary in 2025 as the world’s premier hub for Additive Manufacturing (AM) and industrial 3D printing. Every November, Frankfurt transforms into a global meeting point for experts and innovators who are redefining industrial production with cutting-edge materials, processes, and digital business models.

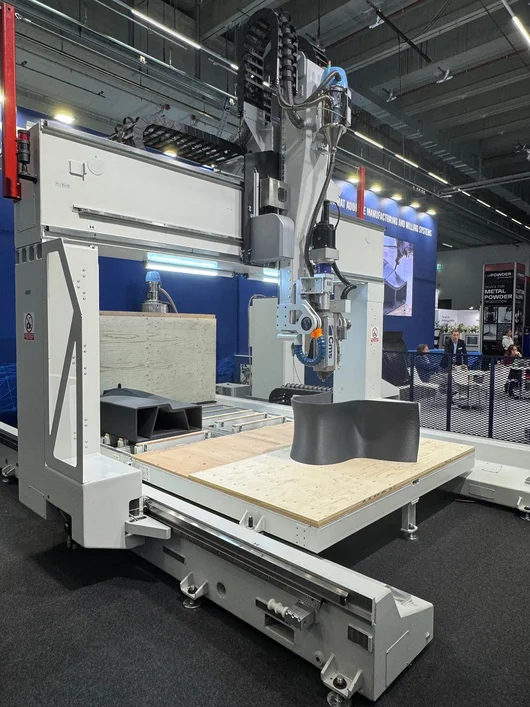

For the 2025 edition, Wibu-Systems will once again join VDMA, the German Mechanical Engineering Industry Association, at their collective booth. As part of VDMA’s Show Case Area “Profitable Industrial Solutions with AM,” we will demonstrate how CodeMeter acts as the secure backbone of digital manufacturing ecosystems, protecting design data, enabling new licensing models, and turning intellectual property into measurable business value.

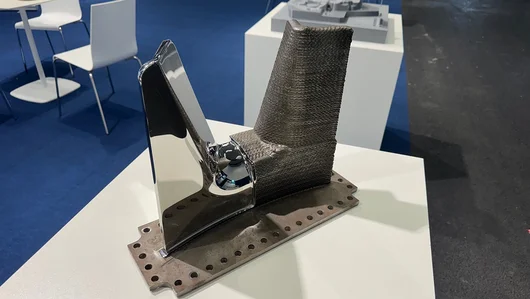

Spare parts at the touch of a button – safe, fast, economical

Displayed in the VDMA Show Case Area, a 3D-printed spare part for a Mercedes-Benz bus illustrates how Additive Manufacturing combined with CodeMeter transforms spare parts logistics into a secure and sustainable digital process. Instead of maintaining large inventories or complex supply chains, components can be produced locally and on demand, with CodeMeter ensuring that only authorized partners access and print the original data. Each production step remains traceable, billable, and tamper-proof, forming the foundation of a modern “digital warehouse” model.

Key advantages:

- Lower capital expenditure – no physical warehousing

- Global responsiveness – local, on-demand production

- Strong IP protection – controlled access and printing rights

- Pay-per-print licensing – transparent, usage-based billing

- Sustainability – streamlined logistics and resource-efficient production

This collaboration between Daimler Buses and Wibu-Systems demonstrates how secure data handling and flexible licensing can turn additive manufacturing into a profitable, resilient, and environmentally responsible business model.

See the Mercedes-Benz 3D-printed spare part live and learn how CodeMeter secures every print.

Protecting and Monetizing Intellectual Property in Additive Manufacturing

From rapid prototyping to serial production, Additive Manufacturing has evolved into a key technology for industrial innovation. However, as design data becomes the core of digital production, protecting it and monetizing it has never been more critical.

CodeMeter from Wibu-Systems secures the entire 3D printing process:

- Encryption of digital designs and print data

- Granular licensing models for preprocessing and printing

- Integration with e-commerce, ERP, and CRM systems

- Traceable usage control via unit counters and license audits

- Deployment flexibility across CmDongles, CmActLicenses, and CmCloud

By embedding CodeMeter in AM toolchains, manufacturers can safely share and sell digital part data, enabling new business models such as pay-per-print, local manufacturing, or distributed production networks – all while ensuring the IP remains protected end-to-end.

Explore how CodeMeter protects digital assets and enables new business models in additive manufacturing.

Insights from VDMA: Additive Manufacturing in Mechanical and Plant Engineering

VDMA’s new whitepaper, Know-how and experience determine success, offers in-depth insights into the value of Additive Manufacturing for mechanical and plant engineering. It explores applications, materials, and business models that make AM both profitable and scalable.

Highlights include:

- How AM extends traditional manufacturing capabilities

- Key use cases for industrial and series production

- Tips for efficient 3D printing in mechanical and plant engineering

- Future trends shaping the AM industry

Download the VDMA Whitepaper “Know-how and experience determine success” and gain deep insights into industrial AM.

Visit us at the VDMA collective booth and discover how Wibu-Systems transforms Additive Manufacturing into secure, efficient, and profitable business. Experience firsthand how CodeMeter bridges innovation and protection from the digital warehouse to the 3D printer.